When you ride low, no matter how careful you are things are going to: hit the ground, get scraped, get dented, dinged and otherwise damaged. Most of these things happen away from prying eyes (oil pans, frame rails, sub-frames, cats, mufflers, etc) but every once and awhile a visible piece like a lip or side skirt to feel the pain.

Having these things repaired professionally time after time, can get quite expensive so a lot of us end up having a go at fixing the damage ourselves. Repairs like these are a great way to get your hands dirty in regards to body work since there is little to no risk of making the problem worse.

The Problem

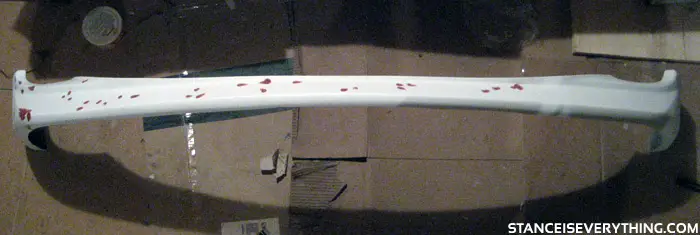

Shortly after putting on my replica fiberglass Garage Vary lip for the season I brain dumped and ran it into a sharp/steep ramp of an unfamiliar underground parking lot.

It sucked, and I was pissed but I had repaired the lip last year after some road debris jumped out at it so I knew that there was nothing stopping me from doing it again.

Supplies

The most important part when taking on any project is making sure that you have all the necessary supplies BEFORE you start, nothing sucks more than getting part way through and realizing you don’t have something you need.

Fiberglass

Fiberglass is what does the bulk of the structural repair you can use mat or cloth, and I currently have both in my garage but for his application I used fiberglass mat.

Fiberglass mat is pretty easy to use, you tear/cut it into portions you need, mix the resin and hardener together, and then apply the resin/hardener mix to the damaged area via a brush.

Once the repaired area is saturated you then brush the mat to get it saturated as well then apply the mat to the damaged area using a stippling technique.

The cloth works in essentially the same way but you cut rather than tear.

A fiberglass repair kit, like the one below, will have everything you need.

Body Fillers

Body filler takes care of the cosmetic portion of this requires using three different levels of fillers: Short strand fiberglass filler (‘kitty hair’), plastic filler (your typical bondo), and spot filler (fast drying filler).

Short strand fiberglass filler

Short strand fiberglass filler is two part (filler and hardener) product that is the hardest and strongest of all of the fillers used in this repair, all of the fillers used after this are appearance level fillers and are not as strong, rigid or durable as fiberglass filler.

Plastic Filler

The second type of filler used will be plastic filler, generally when people refer to ‘Bondo’ this is the type of filler they are talking about. Similar to fiberglass filler this a filler/hardener combo but it does not contain any fiberglass and is therefor easier to sand but offers less structural support.

If you repair cracks with only this type of filler there is a good chance it will crack and fall out later.

Spot putty

The final type of filler used in this project is “spot” filler. It’s pre-mixed filler than provides little to no structural support but is great for filling small imperfections, pinholes and stone chips. It sands out very easily, provided you let it dry completely first.

It also comes in a UV version that will dry faster if you leave it in the sun.

In regards to brands of filler, I currently use ‘Bondo brand’ because it’s what Canadian Tire stocks and had I bought a bunch of it from a previous project (for my e30) so I still had quite a bit left over.

However it is considered relatively low grade and a lot of guys won’t touch it so if you can find Ever coat pick some up.

Sanding Materials

You will need the following grades of automotive sand paper to do a good job:

80,100, 180, 220, 320 (Initial sanding, Fiberglass filler, Plastic Filler, spot putty)

400, 600, 800 (Spot putty, primer coats leading to color)

To do an exceptional job you will also need:

1000-2000 and rubbing compound (Removing runs, dust, orange peel)

Note: Color sanding always seems to bite me in the ass (spray paint is easy to sand through) so I take special care to avoid runs and try and lay the paint as smooth as possible so I can avoid this step.

A sanding block is highly recommended as not only does it make the sanding even it makes it much easier to do.

Paint

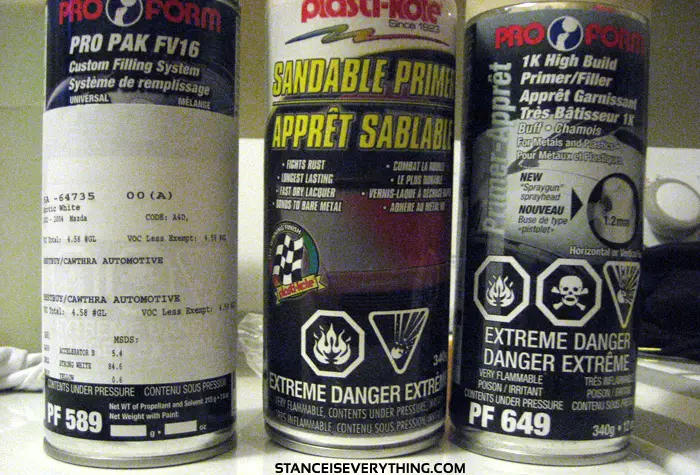

You will need at least 3 different types of paint for this type of job: Sandable primer, High-build primer, Primer sealer (if working with metal), base/clear mix (this is what I had) or base and clear in different cans, or if you have on available a compressor, paint gun, and proper automotive paint.

I get all of my paint material from Cawthra Automotive since they have a wide variety of automotive supplies and will mix rattle cans to your paint code. I have received the odd bad paint can from them but most of the time the results have been good.

From what I understand NAPA also mixes paint in cans for you but none of the locations withing 30 minutes of me do so.

Misc supplies

Additional things that you will need for this project are: mask, safety goggles, a sanding block, a tack cloth, and a trigger for the spray can if you feel necessary (can really help when using standard spray cans).

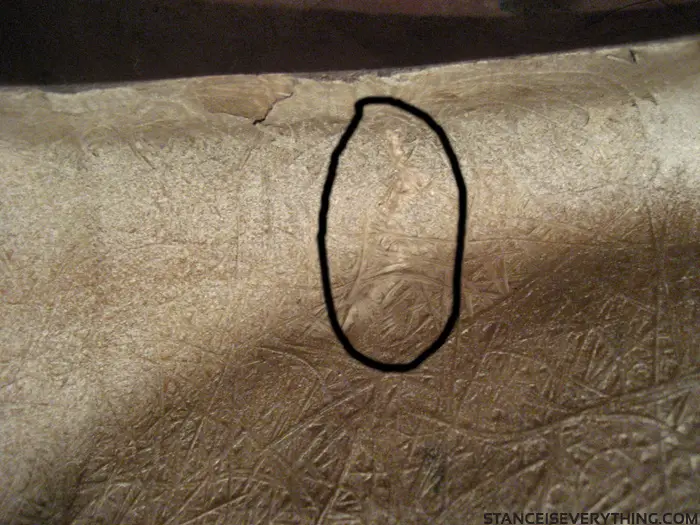

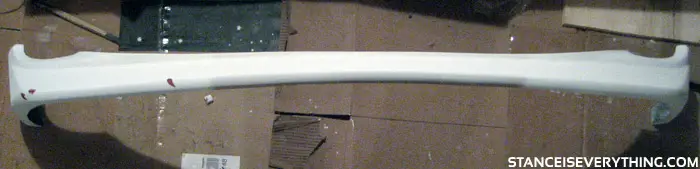

Assessing the damage

After assembling all the materials and supplies above it’s time to get down to work and the first thing to do is assess what you are working with.

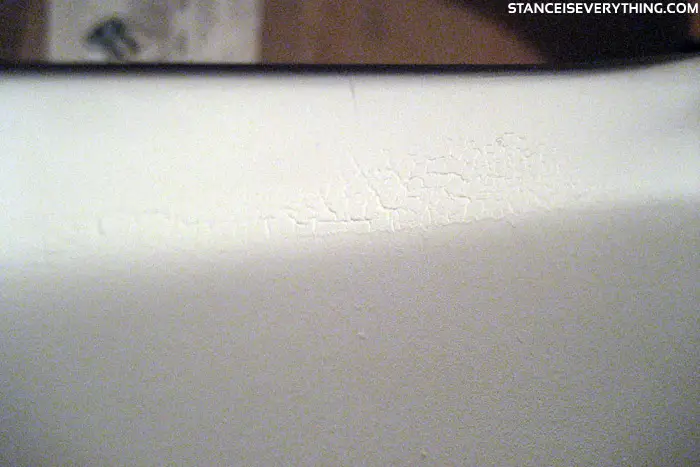

The first step in the repair is to remove the paint chips, cracked filler, etc to really see what kind of damage you are working with, first glances can often be deceiving when doing this kind of repair.

It was easy to tell that the front needed to be repaired but, after careful evaluation, I also chose to do the job right and repair the back as well so that the lip would have some of it’s structural integrity restored.

Once you have assessed your damage read the instructions on how to use your materials before proceeding, not knowing how to mix fillers correctly just leads to more wait time and a longer process over all.

Once you are satisfied that the area is structurally sound you can begin the long process of completing the finishing work to the visual area of the lip.

Be warned there is lots, and lots, of sanding ahead.

At this point you are ready to lay your initial coat of primer. I neglected to take any pictures of my priming process but here are some general best practice tips:

- Make sure your cans of paint are warm

- Make sure that the area you are painting in is over five degrees celsius

- Wet the floor to limit the amount of dust you stir up

- Cover anything you don’t want painted

- Take your time

- Maintain an 8-12inch distance from the object being repaired

- Use a lot of light coats over one thick coat

After this round I sanded the lip with 400 grit sandpaper (instead of 320) and applied some high build primer to the areas I thought needed a little bit more help.

Once the high build primer was dry I sanded once again with 400 grit sandpaper and did a final coat of primer.

After the final primer coat I sanded the entire lip with 600 and then 800 grit primer so that I would have the smoothest surface possible for the base coat to be applied. The goal is for the base coat to go on as smooth as a surface as you can get it.

I have been driving around with this lip installed for the entire summer now and took my new drop pictures with it on. The paint and repairs have been holding up quite well considering I have kissed it on the ground more than once and put quite a few km’s on the car.

I have yet to perfect my method to the point where I can exactly match factory paint with rattle cans but I just picked up another lip which needs no repair and just paint for a steal so I should be able to try this process out again and see how much better I fair.

If you got this far hopefully you found this tutorial helpful and if you do use it to repair one of your own lips I would love to see the results.

Happy sanding!

ridebmx!

Yes I do indeed ride

Noticed by the Sunday sticker haha, go figure.

Lot’s of good articles and photos on coverage everywhere..I’m from Cali myself actually though.

sick DIY. the results are of professional quality gauging from the pictures.

Not quite pro quality but no one has noticed it’s a diy so far 🙂

i HATE glass work moastly i end up doing it on boats and once even a padal boat shaped like a swan! my love of classics has cept me away from automotive grp repair thank god i did help a friend out with a riliant simiter once tho ,nice job dave

Really nice article, I will actually add it in my blog page, where you can find more auto body repair tips and tricks – http://mikesautosvcs.com/professional-body-repair-vs-diy-vehicle-repair/